UNI EN STANDARD

Before 2004 there was no Standard regulating the production and marking of drainage channels. The issue of EN 1433:2004 was a step forward in manufacturing high-quality products in compliance with the CEN (European Committee for Standardisation).

This European Standard defines the requirements for linear drainage channels for the collection and conveyance of surface water when installed within areas subjected to pedestrian and/or vehicular traffic.

The updated Standard UNI EN 1433:2008 specifies definitions, classes, design and testing requirements, marking and quality control for drainage channels.

It also establishes the conditions for the CE marking of drainage channels. The clauses of this European Standard meet the requirements of the mandate given under the EU Construction Products Directive (89/106/EEC) and the relevant strict and precise technical regulations on designing and manufacturing criteria.

The CE marking to affix must be indelible and clearly visible on the product. It guarantees that the product meets all the essential protection and safety requirements for the consumer. The CE marking is to be seen as the passport for the free movement of the product within the Common Market.

Axhell Drain Srl has focused on the quality and safety of its products, thus being granted the corporate certification ISO 9001:2015, ISO 14001:2015, ISO 45001:2018 and the product certification according to EN 1433:2008 for the complete range. In order to ensure all essential safety features, the CE marking has been affixed on all the products.

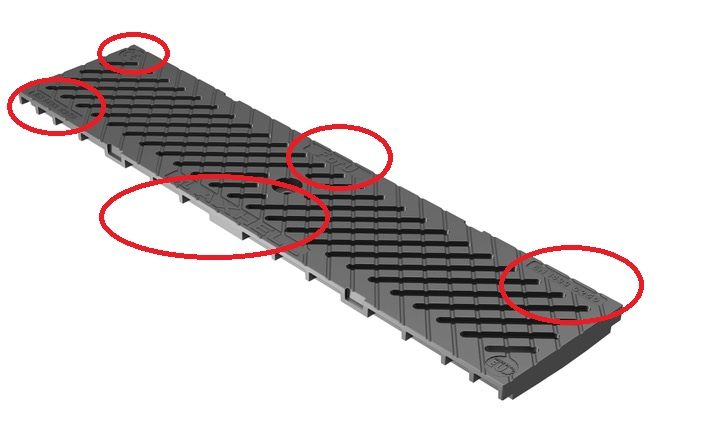

Grating marking

The gratings must be marked as follows:

- Standard number EN1433

- load class

- name or identifying mark of the producer

- name or identifying mark of the company marketing the final system

- production date or lot

- certifier mark

- EC compliance mark

The following mark may be added:

- product identification (commercial name from catalogue)

Drainage Channel

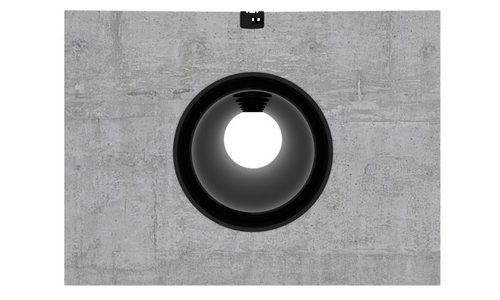

The European Standard EN 1433 defines a DRAINAGE CHANNEL as “a linear assembly composed of prefabricated units permitting the collection and conveyance of water along its total length”.

The Standard also distinguishes “Type I” channels from “Type M” channels. By definition, the former “require no further support to accommodate the vertical and horizontal loads in service”, while the latter need additional support.

TYPE I

TYPE M

The DRAINAGE CHANNEL is a drainage line whose length varies according to the different needs and cases. It is made up of a certain number of units defined as grid units”.

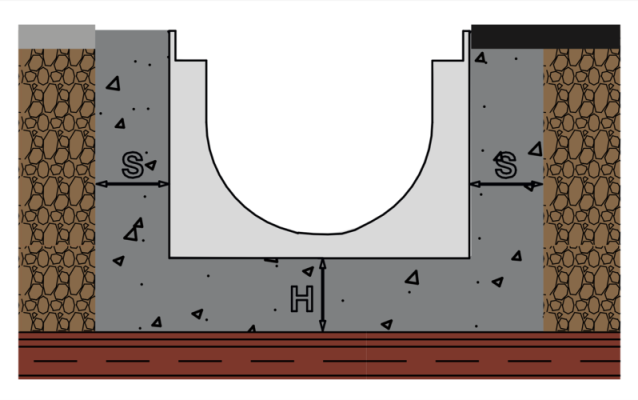

In compliance with 7.17 of the Standard, the “manufacturer” is required to provide the “instructions for specific haunching of drainage channel units”. The following information must be given too: dimensions of concrete bed (H) and haunching (S), the concrete class required, and reinforcement details if any, to meet the load classification on the product at the place of installation.

Standard EN 1433 defines a DRAINAGE CHANNEL as “a linear assembly composed of prefabricated units permitting the collection and conveyance of water along its total length”.

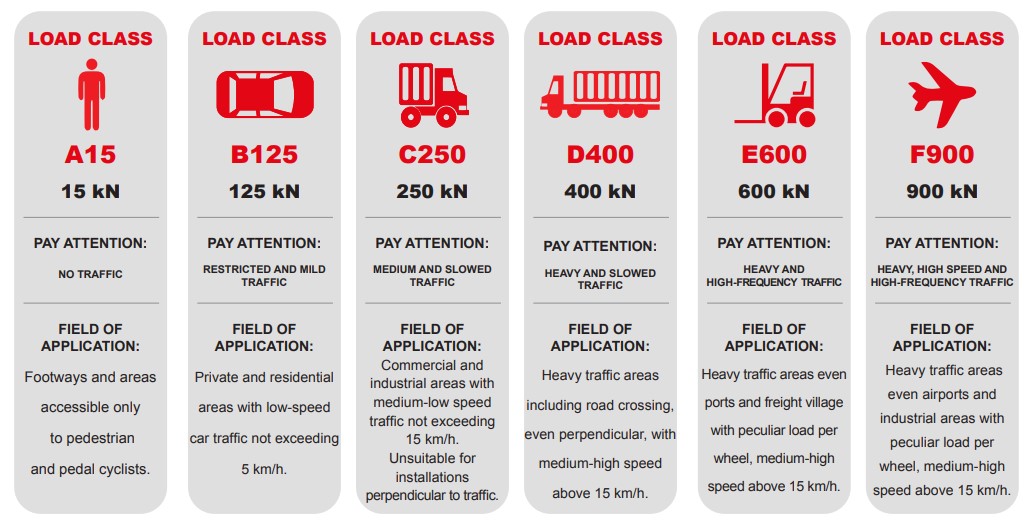

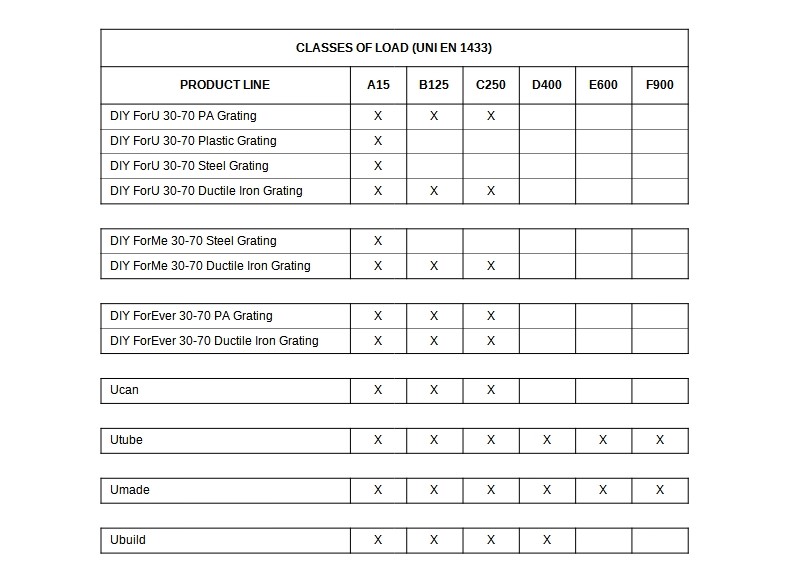

Load Standards for Rainwater Drainage

The European standard EN1433-2004 “specifies requirements for linear drain- age channels for the collection and conveyance of surface water when installed within areas subjected to pedestrian and/or vehicular traffic”.

This standard defines the application areas and loading classes (§ 4 e 5), materials (§ 6), design and construc- tion requirements (§ 7) and the tests that must be carried out in order to demonstrate the compliance with the standard norm (§ 9).

Moreover, EN1433-2008 has been developed by the following essential requirements of the European stan- dard related to construction products (89/106/CEE).

Therefore, if the products are in compliance with conditions of Appendix ZA of standard EN1433-2004, the manufacturer can issue the EU declaration of conformity and apply the CE marking on his covers and gratings.

Regarding the loading classes (from A15 to F900), the standard imposes resistance tests (§ 9) to be performed on grates, and then, on the whole system covers + grates + concrete side flanking (concrete type and quantity to be used shall be determined and recom- mended by the manufacturer according to § 11). These tests have the aim of defining the “grate unity” belonging to a determined loading class.

Tests shall be carried out with specific tools opportunely set and certified (hydraulic presses, gauges, transducers, digital manometers, test blocks, etc..).